Precision Farm Management: From Uncertainty to Profitability

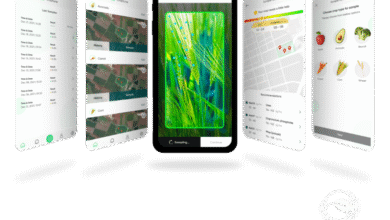

This approach uses new technologies for data gathering and processing

It has been argued that farming is a type of gambling, and in recent years more and more farmers worldwide have been experiencing hard times for various reasons, resulting in reduced profitability.

In order to reverse this trend and minimize the ensuing risk, many farmers have realized that they must find ways to make growing produce more efficient at all stages of the process.

The best way to reduce production and labor costs is to adopt “precision agriculture” methods. This approach uses new technologies for data gathering and processing, enabling farmers to use resources precisely in the production process – whether regarding irrigation and fertilization or managing labor resources, quality control or output management.

These concepts are borrowed from production process management in an industrial factory, and in recent years farmers and analysts as well have indeed realized that the key to efficiency and increased output may be found in relating to the farm as a production facility.

Ori Ganot and Yoram Gommershtadt, two of the four founders and owners of PickApp Farming Ltd., have personally experienced this reality. As owners of a farm that has gone through challenging years of raising peppers, whose price has plummeted due to fluctuations of currency exchange rates, they understood that the only area that can be controlled is labor, which constitutes about 40% of their overall costs. In other words, only by making labor more efficient will they succeed in continuing to manage the farm profitably.

PickApp has developed software for making farms more efficient, a management tool that enables the farmer to measure farming activity, primarily such as is performed by laborers, and is therefore intended especially for labor-intensive crops such as vegetables, herbs, berries, deciduous and citrus fruits.

Examples of system operation

During harvest time, each crate is marked with a barcode which has its unique ID. Before the crate of produce is loaded onto the trailer, the worker scans the barcode using a dedicated application. This scan uploads to the cloud-based system all information connected with the harvest of that same crate (and block/sub-block/row), including information about the picker, production and output.

In case other agro-technical activities are involved, each row of plants is marked with a barcode that indicates its location within the plot. Upon conclusion of treatment, the barcode is scanned, thus monitoring work progress at the worker level.

Ori Ganot: “Unlike other companies, we aren’t based on manual data entry. Data is uploaded to the system by means of scanning the barcode by the workers themselves, or by the work managers, simply and reliably without typing. The system is installed using a dedicated application on a cellphone, which usually serves a team of about 10 workers. At the same time, the data is uploaded to the Cloud in real time, provided that there is cellular communication. Even if there isn’t cellular communication, they can continue to work offline until communication is restored.”

What does the farmer using the system receive?

This system has two outstanding benefits: One is to receive data via cellphone in real time, and the second is continuous data collection that allows the farmer to receive and analyze periodic reports.

Our role, Ori says, is to make information available to the farmer. We understood that the application isn’t always a friendly tool for all farmers, and so now the system automatically sends a daily, organized report via email that includes information like how much each worker picked, when he began to work and when he finished, and even enables an SMS notification that the workers have reached the field.

Specification, implementation and guidance in the Covid-19 era

Making software compatible requires acquaintance with the client and specification of the system. Ori notes, “Until the past year, we used to go to the installation site to learn about the client and his needs, but Covid-19 and the force of circumstances have made us able to install the program remotely, and frankly, it works quite well! In order to prepare to work remotely, we invested in producing tutorial videos for operating the system independently, and we have made the entire registration process automatic.”

Ori relates that “we recently implemented the system in a large farm in Abu Dhabi. We set up the farm digitally with locations for each barcode that we send to the farm, provide on-line instruction, and within a week and several rounds of guidance for the farm managers, the farm runs independently.”

System advantages

The system can monitor worker output and keep track of each row’s production. Since workers know that they are being measured at any given moment, their motivation to invest effort increases. Over time, the system creates a work standard. In fact, some of the farms use the system as a management tool, and they incentivize workers according to their output.

But when it comes to harvesting, output is not the only important consideration. The quantity, as important as it may be, need not come at the expense of quality. Thus, a manager can go out to the field to identify a quality issue, – to scan the barcode of the crate or the row in question, and find out exactly who did the work. Thus, using individual feedback to the worker, the system enables the manager to increase the learning effect for his workers.

Ori adds: For example, deciduous fruit is quite sensitive and is stored for long periods. PickApp provides a quality control interface for on-site inspectors, who can use the application to carry out fruit quality sampling, to issue a quality index report and even add photos. Managers can then pinpoint quality issues and react in real time. Farms often work with 100-200 pickers spread out simultaneously over several different plots, performing at high speed. Without a ‘smart” system gathering all the data generated from the field as well as analyzing it and providing real time alerts, it’s very difficult to manage such a complex operation.”

Supervising the controller

In addition, the system can check the efficiency of quality controllers or pest inspectors, special workers whose role is essential to quality management and data gathering. They need to be managed efficiently — whether in terms of outputs or in terms of pest control level. It’s important not to miss a single row or tract.

Statistical tests run by PickApp’s team determined that using the system saves farms 20-30% of labor costs. The system’s potential is great. In any event, each farmer may choose which features to use according to his specific needs.

The system supports several languages, including English, Spanish, Hebrew and Arabic, and is distributed across farms worldwide, primarily in central markets in terms of mass production: Mexico, Spain and South Africa, which serve as America’s, Europe’s and Africa’s – breadbaskets. Over the past year, PickApp has extended its activity, reaching Gulf States such as Abu Dhabi, and a few African countries, including South Africa.

The Company continues to invest in developing and refining the system. In this era of continued inflation of production costs, with growing competition and rising uncertainty, the system is an essential part of every farm.

For more info: http://www.pickapp.farm/en

This article originally published in Precision Agriculture 2021