Improved irrigation in a strawberry glass greenhouse in Denmark

Improving crop health and reducing irrigation system maintenance for berry farm in Skælskør, Denmark

case study

site details

hunsballe grønt is a modern greenhouse operation in denmark, with about four hectares of covered area. they grow primarily strawberries and blueberries under glass and poly-tunnels. the

operation uses an efficient, state of the art irrigation system with fertigation and a mixing tank capable of customized protocols. however, despite the modern irrigation setup,

hunsballe grønt struggled with achieving their targeted irrigation uniformity due to high levels of organic matter present in the irrigation source, an outdoor reservoir. non-uniform irrigation is a serious concern that severely hampers key benefits / characteristics

on-site generation of peroxide ultrapuretm chemical-input free – only water, electricity and air as inputs > 99.99 % purity hydrogen peroxide, no additives autonomous – fully automated operation

cost effective – saves chemicals, storage, handling and labor eco friendly and residue-free – peroxide ultrapuretm becomes water and oxygen after use the health of the plants. lower amounts of water reaching the plant will weaken it and stress it. a stressed plant is also prone to attacks from pests, fungi or diseases.

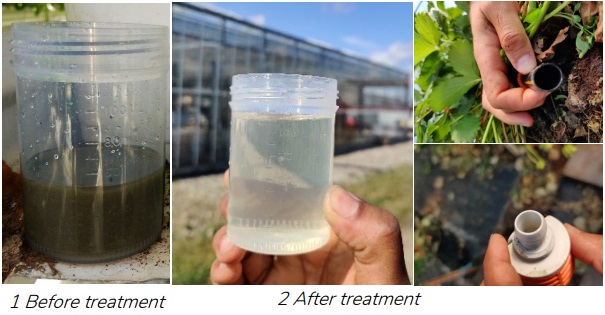

potentially it can lead to plants dying out during a season. it was also clear from the murky water in the lines that a large degree of biofouling was present in the system.

to overcome these issues, an hpgen a500 model was installed and integrated with the irrigation system.

hpgen setup and dosing

the hpgen a500 was installed in the irrigation room and set to operate automatically with a buffer tank. prior to installation, the drippers were analyzed, and a large proportion were clogged, meaning little to no water was coming through them. to overcome this, the drip system would normally have to be replaced between seasons.

dosing: the peroxide ultrapuretm temporarily stored in a buffer tank is dosed into the irrigation lines through the fertigation system. the in-line concentration was checked by measuring the peroxide concentration coming out of the drippers with test strips.

initially peroxide ultrapuretm was only dosing in a section of the greenhouse to compare with the non-dosed section.

results of hpgen treatment

after running with the hpgen for a season, the treated drippers exhibited virtually no clogging, whereas the untreated section had the same performance as before with clogging and non-uniform irrigation.

the benefits of the hpgen system are clear, a more efficient irrigation system where maintenance of the drip lines has been eliminated and delivery of fertilizer optimized. with these results, dripper lifetimes can

be greatly extended, plants remain healthy throughout the season and stand a better chance of fending off attacks from pests, diseases or fungi. from tubing to water exiting the drippers, the system could be maintained in a clean state.

the grower commented:

“we did a trial where we dosed peroxide ultrapure in one section and could compare to a section which didn’t have the treatment. we could see a clear difference in how the drippers were kept clean with peroxide ultrapure, and plants were healthier.” claus hunsballe, owner, hunsballe grønt

with the advantages of the system being clear, the hpgen system was integrated to treat all the sections in the greenhouse.

see a video of this case study in our youtube channel:

https://www.youtube.com/watch?v=5jg674fdvyq&t=4s

learn more about the hpgen system and its benefits for agriculture at:

https://www.hpnow.eu/irrigation-water-treatment/