DryGair’s ‘New Way to Grow’ – The Humidity Control Technology Reducing Horticulture’s Energy Footprint

Humidity control is a crucial part of controlled environment agriculture. Any closed space housing a lot of plants will inevitably become very humid, be it a greenhouse or indoor grow room. However, humidity poses a lot of problems. High humidity leads to disease and mold development, yield loss, slow growth, and lower quality products.

DryGair is leading the way in horticulture humidity control, providing an effective and efficient solution to this widespread issue. The Israeli company manufactures and markets an innovative technology that lets growers control humidity with precision, at the highest efficiency rate.

DryGair’s dehumidification systems take an active approach to humidity control. The company’s flagship unit, the DG-12, removes 45 liters of water from the air per hour (1080 liters per day), using only 10-12 kW, and can completely control humidity in a closed commercial growing space.

Humidity Control’s Energy Problem

Efficiency is important when it comes to dehumidification. The DryGair solution was developed specifically to address one of the biggest issues surrounding humidity control – the energy waste with which it’s normally associated.

Traditional greenhouse humidity control is based on an old technique of heating and ventilating, which is highly inefficient. The method is exactly as it sounds – greenhouse operators ventilate to release moisture, while heating in order to maintain the right temperature range. This leads to excessive heat loss and very high energy costs.

As energy prices rise, heating and venting becomes less and less economically viable, pushing many growers to seek more efficient alternatives, such as DryGair. Growers that use DryGair’s dehumidifiers report up to 70% savings on heating, with an average of 50%.

One study was performed in basil greenhouses in Germany, to measure the impact DryGair has on energy. Over three seasons, the greenhouses using the system exhibited significant savings, compared to the control greenhouses – 42% in the spring, 51% in autumn, and 78% during the winter months. That’s an average of 57%, leading to an ROI of 23 months, based on energy savings alone.

DryGair’s Cultivation Improvements

DryGair was developed to save energy. However, it has since been shown to provide numerous cultivation benefits.

First, as DryGair can control humidity at all times, regardless of weather or climate patterns, it provides the ideal line of defense against diseases. Many of the most common crop molds and diseases, such as botrytis and powdery mildew, require high humidity to develop. So full control over humidity prevents outbreaks at very high rates.

One of DryGair’s customers is Hishtil, an international plant nursery company that focuses on organic production. Hishtil uses DryGair DG-12’s and DG-12 Split units to control humidity in their greenhouses. According to one of the company’s site managers, DryGair almost completely prevents humidity-related diseases. This allows the company to use close to zero toxic sprays, while preventing the yield loss associated with diseases.

DryGair has already proven itself as an all-round growing tool with multiple yield benefits. For example, in a separate trial performed in a Spanish tomato greenhouse, the system provided a 25% increase in fruit per plant, effectively increasing the yield per square meter.

Patented Air Circulation Creates Uniform Growing Conditions

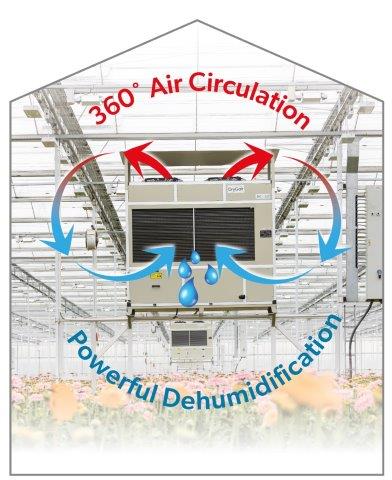

Another benefit of DryGair is its patented air circulation system, integrated in all of their models. The air circulation mechanism uses powerful fans and a unique module to disperse the treated air in all directions, 360°, with enough force to cover large-scale growing spaces.

Proper air circulation ensures effective humidity control in all areas of the space, including far corners, as well as inside dense foliage. This creates homogeneous conditions throughout the entire space, which isn’t just ideal for disease prevention, but also promotes uniform growth and high consistency.

Technology Developed at Israel’s Volcani Agriculture Research Organization

The innovative technology behind the DryGair system was developed at the Volcani A.R.O., Israel’s agricultural research center. It was developed with one mission in mind – to solve the problem of humidity in controlled environment agriculture, in an energetically efficient manner.

The DryGair system became commercially available in 2010, with the formation of DryGair Energies Ltd. It has since proven itself as a successful energy saving and cultivation improving tool. In the past 13 years, the company has sold and supplied units to hundreds of commercial growing facilities around the world.

DryGair’s dehumidifiers are compatible with all types of growing facilities and growing techniques, including hydroponics and vertical farms. Its benefits are applicable to almost all crops, including vegetables, leafy greens, ornamentals, cannabis, and more.