Agrivoltaics in protected cultivation

With a coverage ratio of the roof with OPV modules, and conversion efficiencies of about 2% nearly all electricity consumption of a greenhouse can be supplied

Meir Teitel* grteitel@agri.gov.il , Maayan Friman-Peretza**, Shay Ozer*

Introduction

An increasing number of indicators point to a worldwide trend of accelerating energy transition from fossil fuels to low-carbon solutions of energy production, which can have profound implications for energy supply and demand in the coming decades. The share of renewable energy can grow from 15% in 2015 to 63% of the total primary energy supply in 2050 (Gielen et al., 2019).

Among renewable energies, photovoltaics (PV) is the fastest growing technology for power generation and it is expected to increase almost six-fold, from a global total of 480 GW (GigaWatts) in 2018 to 2840 GW by 2030 and to 8519 GW by 2050 (IRENA, 2019). Since large areas of land are required for the installation of PV panels, significant attention is given to the optimization of land use. As a result of this, agrivoltaics has emerged in recent years. It promotes co-developing the same area of land for both solar PV power as well as for agriculture. Agrivoltaics eases land-use competition between energy and agricultural production. The potential of agrivoltaics is enormous since it has been demonstrated that the global energy demand could be offset by solar production if <1% of agricultural land is converted to dual-use (Adeh et al., 2019).

Fig. 1. Photo of an OPV module that was used in the study. Dimensions are in mm.

The concept of agrivoltaics can be applied either in the open field or in protected cultivation (e.g. greenhouses, polytunnels). Greenhouses contribute significantly to the enhanced worldwide production of food and ornamentals since they provide a suitable microclimate for plants, thus facilitating good plant growth, an extension of the production period, protection of the environment and obtaining higher and better-quality yields (Gruda and Tanny,2015).

Different approaches to combine crop growth with PV electricity production under the same greenhouse structure were described in the literature in the last decade (e.g. Yano et al. 2009; Yano et al., 2014; Kim et al., 2014; Emmott et al., 2015; Yang et al., 2015; Emmott et al., 2016; dos Reis Benatto et al., 2017; Zhang, et al., 2018; Magadley, et al.,2020). Using the excess solar energy, considering the crop requirements, to produce electricity would: i) provide an income from the sale of electricity; ii) allow the greenhouse to be used throughout the year, and iii) reduce the costs of greenhouse cooling in warm regions (Marucci, et al., 2013).

Fig. 2. Photos of the tunnels. (a) 2018 growing season, 34 days after transplanting (9.7.18) and (b) 2019 growing season, 20 days after transplanting (29.5.19). Right and left panels show the OPV and control tunnels, respectively.

In the middle, a photo of the OPV modules on top of the polyethylene cover of the greenhouse tunnel.

Experimental facility

Experiments were conducted in two similar high tunnels with their axis oriented north-south that were covered by a polyethylene sheet. Semi transparent flexible organic photovoltaic (OPV) modules (Fig. 1), were placed on top of the polyethylene roof of one tunnel (hereafter, OPV tunnel). The control tunnel was covered only by the polyethylene sheet in 2018 and by a polyethylene sheet with a black shading screen (25 % shading) on top of it in 2019. The experiments were done during June-September 2018 and May-August 2019.

Due to the low transmittance of the OPV modules (~20 %) in the photosynthetically active radiation (PAR) range (Friman-Peretz et al., 2019), only about 37% of the roof area was covered by OPV modules to prevent excessive shading. The OPV modules were connected to form strips of 1 m width and about 6.4 m length arranged across the arch of the tunnel roof with 1 m spacings between adjacent strips.

Each tunnel was ventilated by two screened openings, one on the eastern and the other on the western sidewall. Tomato plants were planted in the tunnels on 5 June 2018 and 9 May 2019, respectively. The parameters measured in the tunnels were: air temperature and relative humidity; global solar radiation, net radiation, soil temperature, soil heat flux, air velocity and direction, roof temperature, current-voltage (I-V) from which the maximum power output (Pmax) of OPV modules were determined. Plant parameters, such as leaf temperature, height of plants, number of fruits, average fruit mass, and leaf area index (LAI), were measured throughout the experimental periods. External conditions were monitored by a meteorological station positioned close to the tunnels. Figure 2 shows photos of the tunnels, 34 and 20 days after transplanting in 2018 and 2019 respectively. The right and left panels of the figure show the OPV and control tunnels, respectively.

.jpg) |  |

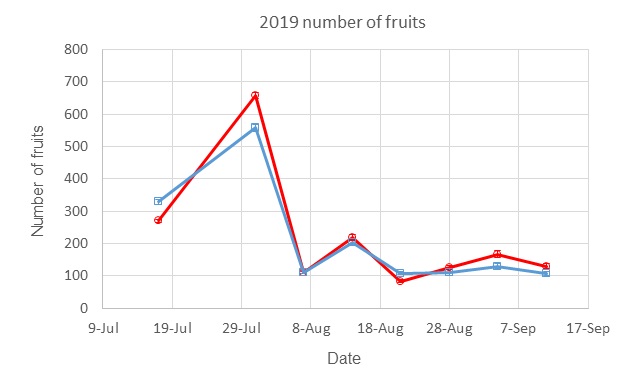

Fig. 3. Number of harvested fruits along the growing season in 2018 (top) and 2019 (bottom).○, OPV tunnel; □, Control tunnel. The error bars represent standard deviation.

.jpg) | .jpg) |

Fig. 4. Weight of harvested fruits along the growing season in 2018 (top) and 2019 (bottom).○, OPV tunnel; □, Control tunnel. The error bars represent standard deviation.

Results

Radiation distribution and microclimate in the two tunnels were examined. Electrical measurements were done to characterize the electricity generation of the OPV modules when placed on an arched greenhouse roof. Yield and a few physiological parameters were monitored throughout the two seasons. The results show that at noon time (from 11:00 to 13:00 when hottest conditions prevail) there was no significant difference in the mean seasonal (June-September 2018, May-August 2019) air temperature and humidity between the tunnels. The mean seasonal air temperatures in the OPV and control tunnels in 2018 and 2019 were 31.0 1.4 °C and 31.9 1.3 °C and 30.3 1.6 °C and 30.0 1.5 °C, respectively. The mean seasonal relative humidity in the OPV and control greenhouses in 2018 and 2019 were 61.5 9 % and 60.5 8 % and 65.3 8 % and 66 9 %, respectively. The main differences in 2018 between the tunnels were in the distribution of solar radiation along the tunnel centerline and canopy temperature. Due to the placement of OPV modules, the seasonal average radiation along the OPV tunnel was much lower (446 Wm-2 against 594 Wm-2 in the control) and less homogenous than in the control. The placement of a shading net on the control tunnel in 2019 resulted in similar shading in the two tunnels and thus similar average radiation levels along the tunnels’ centerlines (433 Wm-2 in the OPV tunnel against 447 Wm-2 in the control).

In 2018 and 2019 the differences in canopy temperature between the OPV tunnel and the control were on average about 1.9°C and 0°C, respectively. The temperature of a module placed on the polyethylene cover was about 50-55 °C at midday, about 12 °C warmer than the polyethylene cover. Monitoring plant development showed that the plants in the OPV tunnel had a higher leaf area index (LAI) than in the control in 2018 and a similar LAI in 2019. Despite the lower average radiation/light intensity in the OPV tunnel in comparison to the control (in 2018), the cumulative yield in the OPV tunnel was generally higher than in the control (see Figs. 3& 4), with a higher average fruit mass (101 g vs 81 g, respectively), apparently due to the lower canopy temperature. In 2019 the cumulative yield in the OPV and control tunnels was generally almost the same (see Figs. 3& 4), with similar average fruit mass (119 g vs 123 g, respectively).

The electricity conversion efficiency of the OPV modules (the portion of solar energy that is converted to electricity by the OPV module) varied between slightly less than 0.5 and about 2% during the day, with the higher values observed when irradiance was lower than 200 W m-2 (Magadley, et al., 2020). It is anticipated that with a coverage ratio of the roof with OPV modules as in the present study, and conversion efficiencies of about 2% nearly all electricity consumption of a greenhouse (mainly in summer), under Israeli climate conditions, can be supplied. Despite the potentially low cost of the roll to roll production of OPV modules, their current price is very high. In addition, their lifetime on top of a greenhouse roof is relatively short.

Acknowledgments

The authors thank Dr. Farhad Geoola, Dr. Esther Magadley, Dr. Ibrahim Yehia, Mr. Asher Levi, Mr. Roman Brikman and Mrs. Shelly Gantz for their significant and constructive help. The study was supported by the Chief Scientist of the Ministry of Agriculture and Rural Development of Israel (grant no. 20-12-0027, the BARD fund (grant no. US-4885-16), and the Plant Production and Marketing Board of Israel (grant no. 459-4540-17).

*Institute of Agricultural Engineering, Agricultural Research Organization, The Volcani Center, HaMaccabim Road 68, P.O. Box 15159, RishonLeZion 7528809, Israel

**Department of Mechanical Engineering, Ben-Gurion University of the Negev, P.O. Box 653, Beer-Sheva 81405, Israel